Flexible modules with SIL2 rated provide project teams and manufacturers with a holistic and customizable monitoring system for hydrogen applications. Changes in voltage or current can provide information about the performance and safety of hydrogen electrolyzers, stacks and fuel cells. The HVT series enables safety-rated measurement and signaling of SIL2 alarms and measurement values. Applications include monitoring of high-voltage DC links in fuel cell powertrains, stack voltage monitoring and busbar symmetry measurement, detection of earthing faults and current monitoring for rectifiers. In addition, we offer flexible devices for safe monitoring of other parameters, such as vent and gas concentration sensors, humidity and temperature, to ensure safety in container electrolyzers and fuel cells.

The electrical energy for hydrogen production is provided as DC current by rectifiers. Before the electrolyser goes under the load of the main rectifier, a smaller direct current from a polarization rectifier is connected to ensure the correct polarization of the individual membranes - For the safe operation of the electrolyser, it is important that all rectifier currents are monitored at a certain SIL level and, for example, a safety-relevant alarm signal is triggered if the critical level is not reached

Download Application Fact Sheet "SIL2 Rectifier Monitoring"

Liquid-carrying lines have a limited electrical conductivity - In the event of a leakage, an electrically conductive connection is established between a high potential (e.g. anode or cathode) and PE (earth fault). An electrical potential can therefore build up on the electrolyser rack at any time, which can lead to an electric shock and thus to a considerable health hazard if touched by an employee - this danger is not recognizable for employees and operators without measurement.

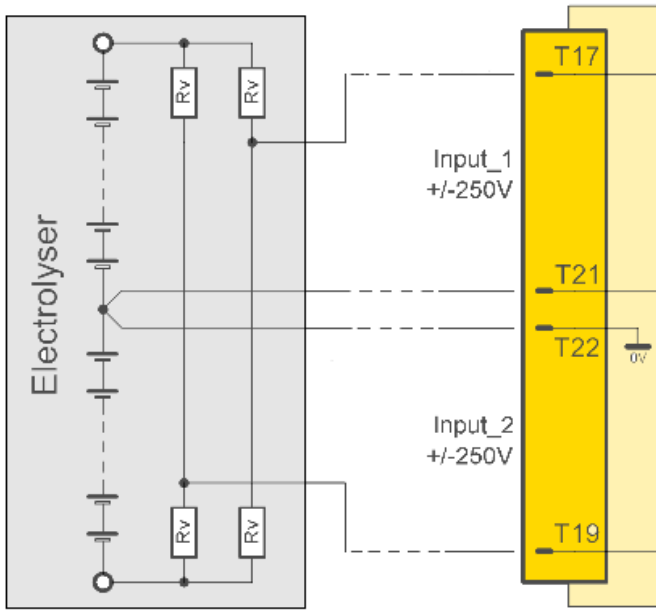

The HVT 300-DP continuously measures the balance across the stack and the busbars so that insulation faults and membrane defects are detected at an early stage and safety-related threshold values for touch voltages are available for the PLC.

Download Application Fact Sheet "SIL2 Ground Fault Monitoring"